Deep press sheet material

De Haak 4 ,5555 XK Valkenswaard

Event informatie

Family business

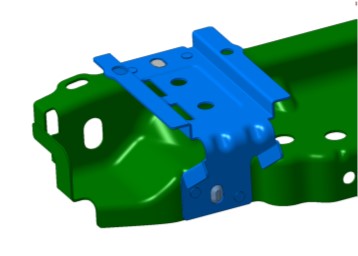

Deep drawing is a shaping technique in which metal sheet is converted into a seam-free three-dimensional shape under mechanical pressure through plastic deformation.

Family business

From our origins we are a family business. That makes us proud, but also very close as a team. Our core values of flexibility and entrepreneurship are expressed in our no-nonsense mentality. That is why we think in solutions. We notice that our many years of experience in the automotive sector builds bridges towards other sectors. This, in combination with our high-tech machinery, enables us to meet any request, complex or not, within very short lead times and at cost-effective prices.

Programma

- 15.05 - 15.15 Event introduction

- 15.15 - 15.30 Where did it start.

- 15.30 - 16.30 Deep drawing shaping technique and its application

Onze sprekers

Mat Josquin

MikrocentrumEvent Moderator: Since 16 years working for Mikrocentrum in different disciplines building bridges between people working in the technical manufacturing industry. The understanding of what is going on in the industry is based upon activities in the field of CAD/CAM/CAE since the early eighties, being involved with the introduction of 3D printing in Europe, and project management of innovative developments in the field of VR, AR and computer animation.

Gerard Maessen

Proven ConceptsGerard Maessen Director of Proven Concepts a company that came about through a collaboration of a group of former colleagues. This indicates that sincere cooperation can bring us great results.

Ron Cornelissen

Proven ConceptsDirector of operations at Proven Concepts. We turn ideas into reality.

Downloads

Informatie PDF

Informatie Externe link

Q&A

1) Do simulate this process before manufacturing Tooling and pressing?

Normally we do not simulate. In all the years we have made pressing tools, we didn’t make simulations. If this is asked or if it is really necessary, we have to do this with an external company. We have at our firm not the software for this.

2) Can you give an indication when series numbers are sufficient to have a business case with deep press sheet metal shaping?

This is very difficult to say. It depends on several items. For example the shape and complexity of the part is here a big issue. There are also more ways to create a part, so we suggest that if you have a part or problem, please contact us and we can start an open discussion to come to a solution.

3) What kind of plastic is used?

For making pressing tools in “soft material”, we use ebablock from Ebalta. Here there are a few types available. Mostly we use the grey material called ebablock W.

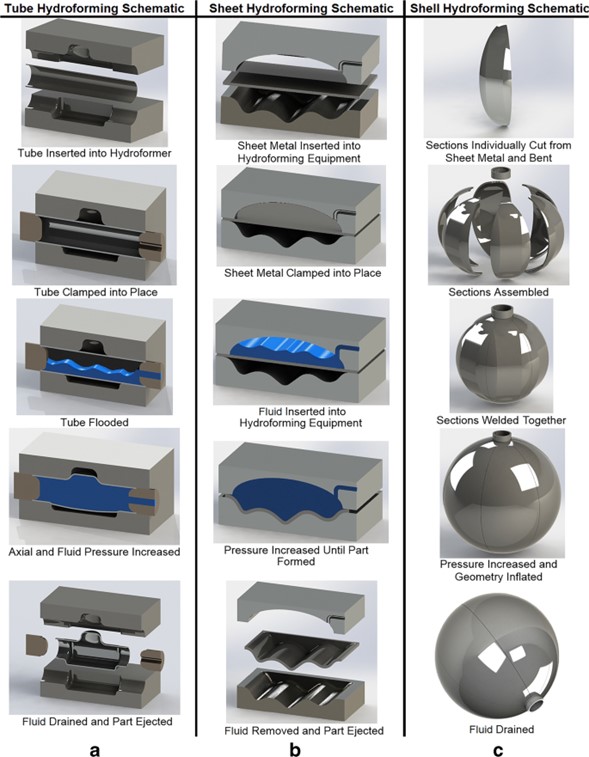

4) How does the method compares to rubber pressing and hydro forming?

With rubber pressing we have also done some experiments here at our company and investigated if it is necessary to invest in a machine. But at the moment this is not the case. The difference is that with rubber pressing you mill just one side of the tooling. When you are making a part, the tool is closing in a rubber block. Not every shape is possible to press with this technique. The more difficult parts need a two side tool, mostly in steel, so that the shape is 100% formed. We mill for our press always two sides in steel or in softtool. The big advantage is, that we can press the part better and the shape will be more tight. Grooves will be better pressed. Hydroforming is a other technique for making metal parts. Also used with tubes. No Rubber form is used on one side, but high pressure is build up with liquid. With this technology you need a “closed system” to get the high pressure. There are different kind of ways to do this, but below you see a sketch. [We are working on adding pictures to the website. Sorry for the delay.]

5) How about cleanliness? Do you use grease in the pressing process to lower friction?

If necessary yes, but first we try without. Also a foam can be used to lower friction.

6) Was the 180deg bend also done while pressing, or by hand?

This is done partly by hand and partly with the pressing tool. We press the edge already in an angle of for example 120deg. After laser cutting, we bend it over by hand. Over the angle of 90deg. Than we put the part back in the tool and press it to 0deg. [We are working on adding pictures to the website. Sorry for the delay.]

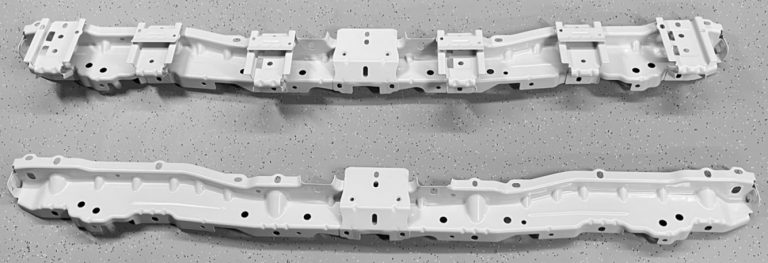

7) With the part consisting of many welded parts; how do you control the shape tolerances?

8) What are typical lead times?

This is difficult to say. Depends on delivery of raw material, capacity at that moment, complexity,… If you have a project where pressed parts are or can be used, please contact us and we can discuss the possibilities. Normally for the tools we need 2-3 weeks. And 1 week for manufacturing the parts.

9) Have you ever tried deep drawing material around a small hole? what were the problems/ issues you encountered?

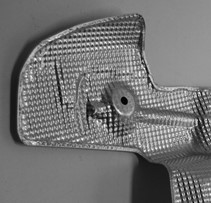

We create the hole with 3D laser cutting after the deep drawing. If this is possible depends on shape of the part and mainly the depth of the pocket. See also pictures at question 10, if this is what you mean.

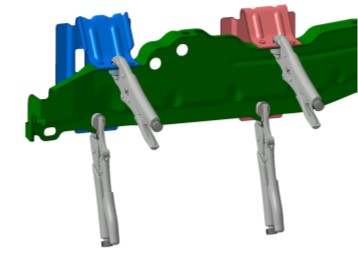

11) You use tooling on every assembly that must be welded together? Or do you add positioning features in the pressed parts?

We do a combination of both. Depending on the quantities and difficulty, we can use holes in the parts and use pins for positioning or the 3D shape of a product. With manual clamps and pins we can do the positioning. Weld it and remove the clamps and pins again. When the amount is high or very small tolerances are asked, we create a welding jig. [We are working on adding pictures to the website. Sorry for the delay.]

12) Can annealing be used during the forming process to enlarge the shape freedom?

For prototyping, yes it could be used, but it is still not very easy to control. For example heating up a small difficult area.

Contact

Beschikbare locaties

- - Online

Beschikbare plaatsen: 78

"*" geeft vereiste velden aan